Spiral Retaining Rings have many advantages over standard circlips however many engineers are still using circlips. One reason for this may be because the installation and removal methods are not commonly understood. Spiral retaining rings can be easily installed and removed with no special tooling or with simple tooling to increase efficiency.

There are many questions and concerns that engineers have had when deciding on a retaining ring. The installation and removal of a ring seems like such a simple element in deciding what ring will work best in an applicationbut it is something that engineers often overlook when designing a ring into an application.

There are a few different ways to install a retaining ring.

Manual Installation: Manual installation on an individual or low production basis is accomplished as follows: 1. Separate the ring coils and insert one end of the ring into the groove. 2. Wind the ring by pressing down around the circumference until the entire ring is inserted into the groove.

Semi-Automated and Automated Installation: For higher speed and automated assembly operations simple tooling and assembly fixtures can be designed. External installation on a shaft can be accomplished with a plunger and tapered plug. The plug angled at approximately six degreesis centred over the shaft end. A loose fitting plunger pushes the ring into position over the tapered plug. An arbor press or air cylinder is commonly used to fully automate this assembly operation.

Spiral Retaining Rings are supplied standard with removal notches to enable easy extraction from a groove. The notch is provided to form a small gap between the ring end and the shaft or housing permitting a blunt object to be inserted at the end of the ring to pry the free end out radially and up.

Insert a screwdriver or dental pick behind the removal notch; use the tool to pry out the first end of the ring; manually spiral the ring around until is it free from the groove.

The equations below are used to check that the elastic stress limit of the ring to ensure the material does not exceeded stress limitations due to installation. To select a safe stress value it is necessary to estimate the elastic limit of the raw material. The minimum tensile strength can be used as a suitable estimate. As with any theoretical calculation a closer analysis of the actual application may reveal that these stress values can be exceeded. However particular consideration must be made to functional characteristics such as installation methodthe number of times the ring will be installed and removed thrust load and/or centrifugal capacity.

After forming the rings natural tendency is to return to its original state. This places the inner edge of the radial wall in residual tension and the outer edge in residual compression. To account for the residual stress in the ring when expansion is taking placeonly 80 percent of the minimum tensile strength should be used to compare to the installation stress; see the table below.

In special or complex designs where the installation stress exceeds the materials elastic limitrings can be produced to diameters which will yield a pre-determined stress during assembly. Once installed the ring will have the proper grip on the groove.

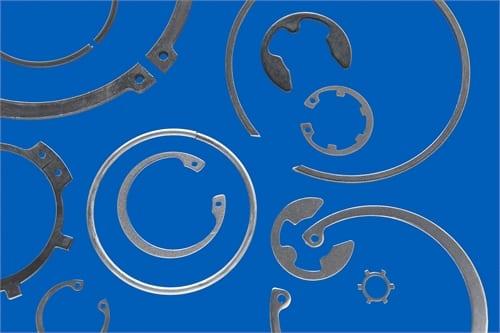

There are many benefits for using a Spiral Retaining Ring verses a standard retaining ring with ears. One of the greatest benefits is having a 360-degree retaining surface with no ears to interfere with mating components in an assembly.Coiling the ring also gives it added strength and stability and because the coiling process produces a product with a circular grain. There is no material waste as opposed to a stamped ring. There is also a lot more flexibility when designing a ring.

The thickness and diameter can be changed to accommodate most any application by either varying material thickness and/or the number of turns in the ring. It also provides a clean appearance to the assembled product.

Have our catalogue sent to your door